Warm Mix Asphalt (WMA) Water Injection System

A PATH TO GREEN FUTURE.

MONTHLY SAVINGS (20 WORKING DAYS)

Fuel saved per ton: 1.4 litres

120 TPH plant: saves ₹14.78 lakh/month

160 TPH plant: saves ₹19.71 lakh/month

200 TPH plant: saves ₹24.64 lakh/month

Based on 20 working days, 8 hrs/day, 20% fuel reduction.

Warm Mix Asphalt (WMA) Water Injection System

A compact, plug-in module that injects precisely metered water into hot bitumen to create controlled foaming—enabling asphalt production at 20–40°C lower temperatures. Plant owners typically see up to 20% fuel savings, faster compaction, cooler worksites, and annual carbon reductions of ~1,500–2,000 tCO₂ per unit.

Key Benefits

Cut Fuel Use (~20%): Lower burner demand without sacrificing mix quality.

Cooler, Safer Operations: Reduced heat exposure for crews and surrounding communities.

Same or Better Performance: Maintains workability, density, and rutting/fatigue resistance.

Rapid Payback: Savings on fuel and maintenance often offset the investment quickly.

ESG-Aligned: Tangible CO₂ reductions that support sustainability goals.

How It Works

The system injects micro-quantities of water into the bitumen line to create a fine foam. This increases binder workability at lower temperatures while maintaining the perfect mix quality as HMA.

Features

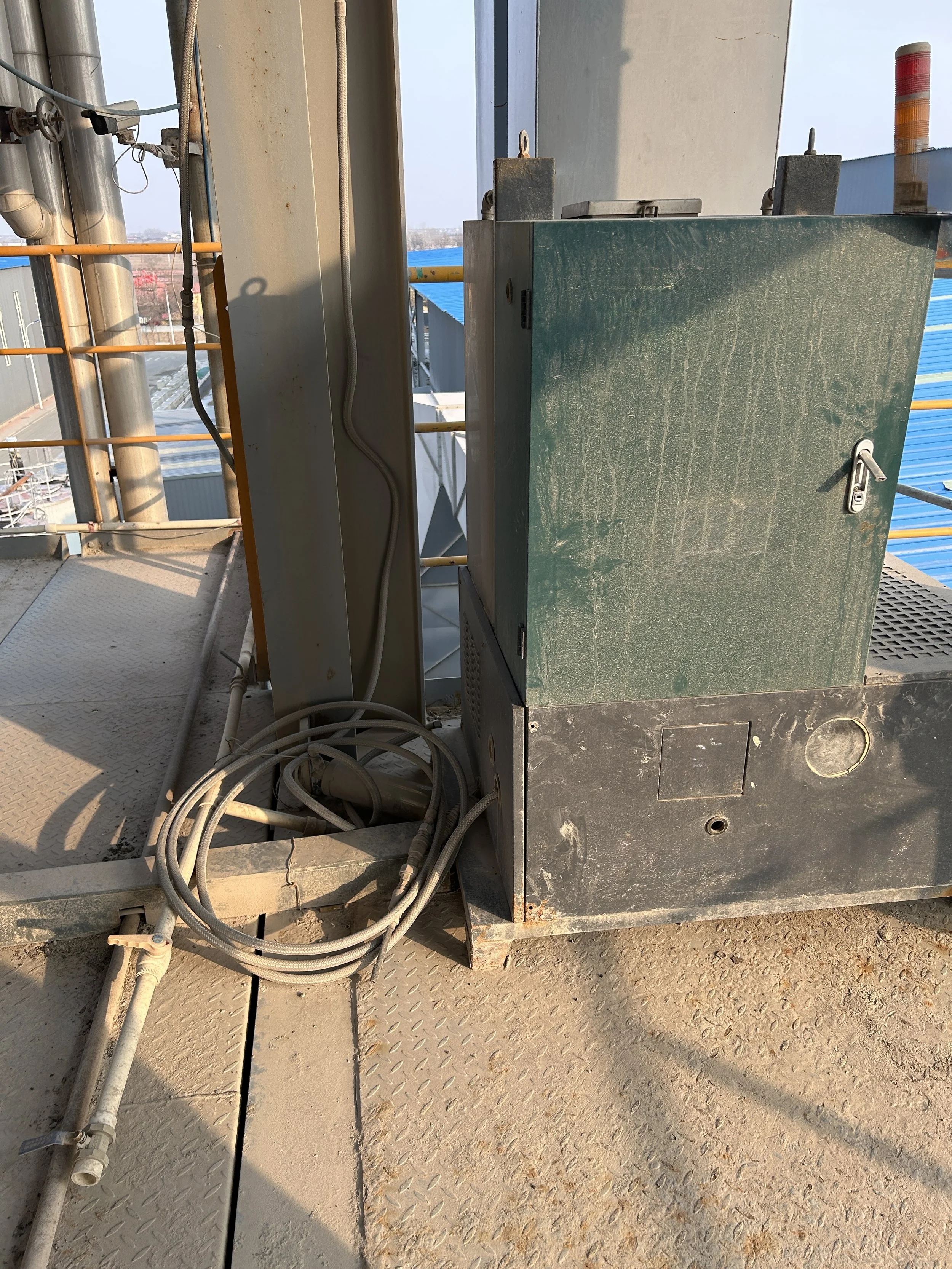

Closed-Loop Control: PLC/HMI with precise flow and temperature logic.

Retrofit-Friendly: Integrates with any asphalt batch mix plant.

Compact Footprint: Skid-mounted unit for quick installation and service.

Safety-First Design: Interlocks, alarms, and automatic shutdown logic.

Low Maintenance: Industrial pumps, stainless lines, and accessible filtration.

Typical Results

Temperature Drop: 20–40°C below conventional HMA.

Fuel Savings: Up to 20% reduction in burner fuel consumption.

Carbon Impact: ~1,500–2,000 tCO₂ avoided per unit per year

(≈ taking ~400 cars off the road or planting ~70,000 trees).

*Actual results depend on plant capacity, fuel type, aggregate moisture, and operating practices.

Compatibility & Integration

Plant Types: Batch plant.

Control: PLC/HMI; supports common plant signals.

Utilities: Power (3-phase), process water line, network (optional).

Install Time: Typically 1–2 days with commissioning.

Support & Services

Commissioning & Training: On-site/remote options.

Warranty: Standard coverage with optional extended service plans.

After-Sales: Spares, calibration, and performance audits by DPC.

Ideal For

EPCs, contractors, and plant owners pursuing fuel savings, ESG targets, and improved site safety—without changing mix designs or adding chemical additives.

Call to Action

Ready to cut fuel and carbon?

Contact Dynamic Pro Civil for a site assessment, ROI estimate, and installation plan.

FAQ

Will WMA affect mix performance?

No—WMA maintains or improves workability and density at lower temperatures when properly controlled.How soon do we see savings?

Immediately upon deployment; payback depends on plant throughput and fuel price.Is it compatible with RAP?

Yes—cooler mixes often improve workability with RAP; results depend on RAP %, binder, and moisture.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!